Are you mastering the shortage of semiconductors or other challenges better than the competition? The use of a suitable SAP solution in production can yield a decisive advantage. The solutions are aimed at accelerated time-to-market, more efficient manufacturing, and cost reductions in production. The use of best practices reduces the effects of bottlenecks and creates new scope for action. In the following, we are presenting 5 current SAP software solutions for manufacturing.

5 solutions from SAP at a glance

For manufacturing companies, SAP offers different standard solutions in the areas of production, product development and logistics processing.

- SAP Digital Manufacturing Cloud

- SAP Manufacturing Execution

- SAP Manufacturing Integration and Intelligence

- SAP S/4HANA Manufacturing

- SAP Environment, Health, and Safety Management

These can be implemented in companies with the help of best practices. We would be happy to support you with individual solution customizing. Below, you will find a brief overview of the relevant tasks of the individual solutions:

Solution 1: What is SAP Digital Manufacturing Cloud (DMC)?

Manufacturers have a Manufacturing Execution System (MES) at their disposal with the SAP Digital Manufacturing Cloud (SAP DMC). This is responsible for production control and focuses on the execution, data analysis, control, and integration of manufacturing processes. The solution is provided entirely via the cloud as Software as a Service (SaaS). The future will show to what extent this cloud solution is suitable for controlling and mapping a shop floor.

Solution 2: What is SAP Manufacturing Execution (ME)?

The production solution SAP Manufacturing Execution (short: ME) reduces quality and productivity problems as well as warranty and liability risks. It is a web-based MES system. With this, companies can manage and control production processes, production-related processes and compliance. For this purpose, SAP ME records and documents the processing of raw and production materials. However, very different processes can be mapped and successively introduced. This keeps the costs involved in the rollout to a minimum. In contrast to SAP DMC, the standard integration with other SAP modules is already included in the on-premise solution and the user interface is easier to use. In a way, DMC is the SaaS supplement to the business model. Artificial Intelligence (AI for short) supports the root cause analysis in the event of irregularities or efficiency losses so that these are cushioned. SAP ME covers the following main requirements:

- Serialization

- Track & Trace

- Data collection

- Process control and QM in production

- User interfaces for production employees, work instructions and much more.

Solution 3: What is SAP Manufacturing Integration and Intelligence (MII)?

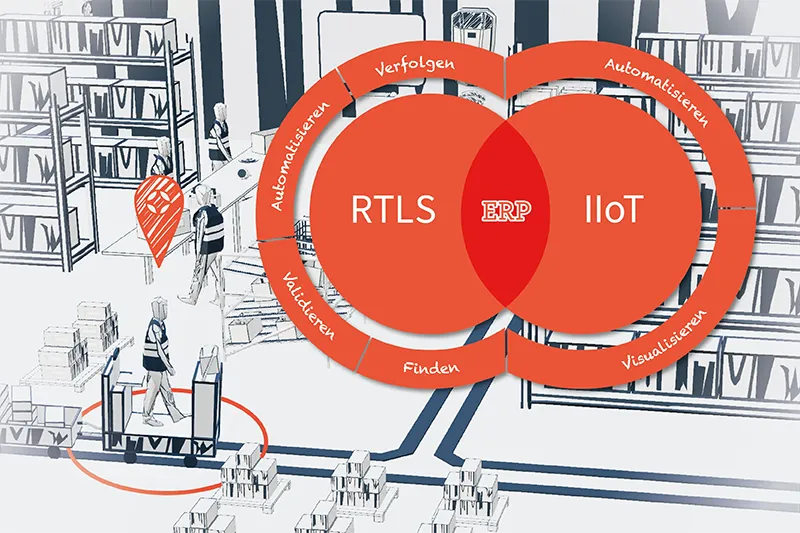

Although the digital mapping and control of production processes is important for establishing networked production, it is only a first step. Real added value only arises when production data is integrated into ERP and business data. This integration and visualization of data is one of the most important tasks of SAP Manufacturing Integration and Intelligence (SAP MII for short), as is the integration of master and transaction data between MES and SAP ERP. Master data are, for example, material, bill of materials, workplaces and work schedules. Transaction data includes production orders and production confirmations. In addition, integration in non-SAP systems is also conceivable.

Solution 4: What is SAP S/4HANA Manufacturing?

The SAP module PP was combined under S/4HANA in the manufacturing or production business areas. Manufacturing companies network all production processes with the S/4 solution. The mapping of the processes in real time, enables flexibility in planning, management, and control. As an example, just-in-time deliveries can be better managed. As the SAP maintenance for the PP module expires in 2030, a timely changeover is recommended. At the same time, this occasion offers a good opportunity to question and optimize internal business processes.

Solution 5: What is SAP Environment, Health and Safety Management?

Another important solution is the SAP Environment, Health and Safety Management (EHS for short). The solution is integrated into the SAP ERP and SAP EWM. The focus is on ensuring the defined risk management in order to prevent incidents in operational safety. In the event of damage, costs and information are recorded or documented in the areas of occupational health and safety. Overall, the EHS solution enables companies to meet their verification and documentation obligations. It facilitates work in sensitive areas such as waste management or dangerous goods handling. In this way, corresponding processes can be carried out in accordance with the law and employees and production goods can be protected.

Do you have any questions regarding the currently 5 most important SAP software solutions in manufacturing companies?

We would be more than happy to assist you with our consulting and development services. Any questions? Feel free to contact us at any time.